In lots of circumstances, content is rolled in the mill in both Instructions to assist in deep drawing. This causes a more uniform grain structure which restrictions tearing and is also referred to as "attract top quality" content. Increasing[edit]

The gooseneck punch is mainly employed for bending “U” formed parts having a deep depth. The hemming punch is mainly employed for flattening sections.

Having said that, on account of variations in the material thickness for bending, the exact same punch and die cannot be utilized for a person-time bend forming.

Growing is really a process of cutting or stamping slits in alternating sample very similar to the stretcher bond in brickwork after which you can stretching the sheet open up in accordion-like vogue. It can be Utilized in apps the place air and drinking water move are preferred along with when light-weight weight is wished-for at price of a sound flat floor.

Rolling is metal Performing or metal forming approach. In this process, inventory passes by means of one or more pair of rolls to scale back thickness. It really is accustomed to make thickness uniform. It is classed Based on its temperature of rolling:[22]

This can be the most typical sheet bending approach as it's applied for the majority of bending projects. It employs an instrument referred to as the punch and v-die to bend sheet metals at preferred angles. In the course of the process, the bending punch presses over the sheet metal put about the V-die.

According to the Metal Roofing Alliance, metal roofs can read more very last fifty years or for a longer period, building them an ideal roof form for extended-time period safety. Examine our complete Price tutorial to learn should they’re the proper choice for you.

The fiber direction on the expanded product. In order to avoid breaks, the way in the fibers with the expanded materials is usually altered so that they are perpendicular towards the bending line, or an annealing procedure might be executed over the bending components for making them more versatile.

For a standard press brake device, In case the bending peak H is larger than or equivalent to 80mm, the part will interfere Using the machine through the bending approach.

Close-by holes may well get warped If the holes are far too near the bend, they may get deformed. Round holes are certainly not as problematic as other types but your bolts may still not in shape as a result of. Again, begin to see the bending pressure chart for minimum amount flange measurements and put the holes farther compared to least.

A different point to remember right here is the bending radius. The more substantial The within radius, the bigger the springback influence. A pointy punch gives a small radius and relieves the springback.

Aluminum sheet is on the market in a variety of kinds, giving fantastic weldability and formability along with strong corrosion resistance.

At RapidDirect, we offer CNC punching abilities which can create holes as much as fifty mm in diameter. This method allows for exact and effective gap punching, making certain that the final product or service fulfills all needed technical specs and benchmarks.

Sheet is calculated in gauges, contrary to plate and that is measured in inches. Thicker materials is named plate and is obtainable right here.

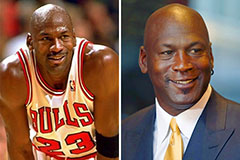

Michael Jordan Then & Now!

Michael Jordan Then & Now! Gia Lopez Then & Now!

Gia Lopez Then & Now! Rachael Leigh Cook Then & Now!

Rachael Leigh Cook Then & Now! Jane Carrey Then & Now!

Jane Carrey Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now!